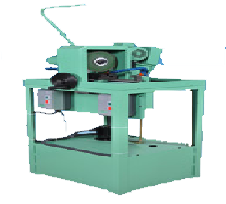

CARBIDE PARTING

- Wet Grinding - No carbide dust & no need to use industrial mask.

- No necessity to face grind after cutting

- Wheel life of 10,000 cuts of dia12 approx.

- Low cost for cutting the solid carbide rod

- Recovery of carbide powder from the used coolant.

- Manual cutting infeed of the cutting wheel.

- Dry Cutting of the carbide rods changes its micron structure. Wet grinding keeps it's structural integrity intact.

| Downloads |

|---|

| Reach Us |

|---|

Plot No.467 - 469, 12th Cross

4th Phase , Peenya Industrial Area

Bangalore - 560058 |