ACCUDRESS PRO

ACCUDRESS PRO

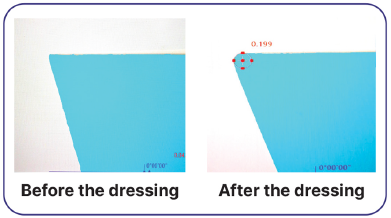

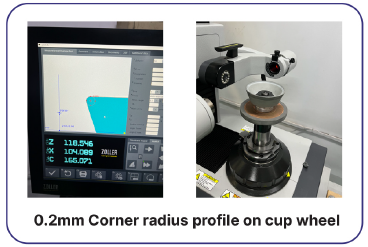

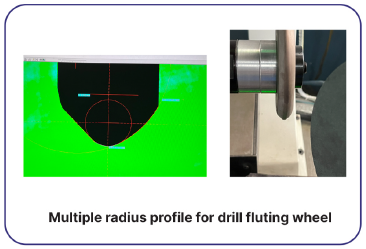

- Wheel corner radius gives definable geometry to the grinding wheel.

- As you define the value of corner radius of wheels, the software is able to create a perfect program.

- Perfect program gives a precise CNC code (program). This precise CNC code produces a high accuracy cutting tool like end mill, drill & profile tools, when run on a CNC tool grinder.

|

|

Measuring software has the following features:

|

|

|

|

|

|

|

|

|

|

|

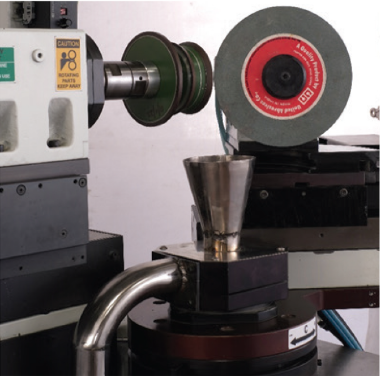

ACCUDRESS PRO MACHINE BASE

|

| Downloads |

|---|

| Reach Us |

|---|

Plot No.467 - 469, 12th Cross

4th Phase , Peenya Industrial Area

Bangalore - 560058 |