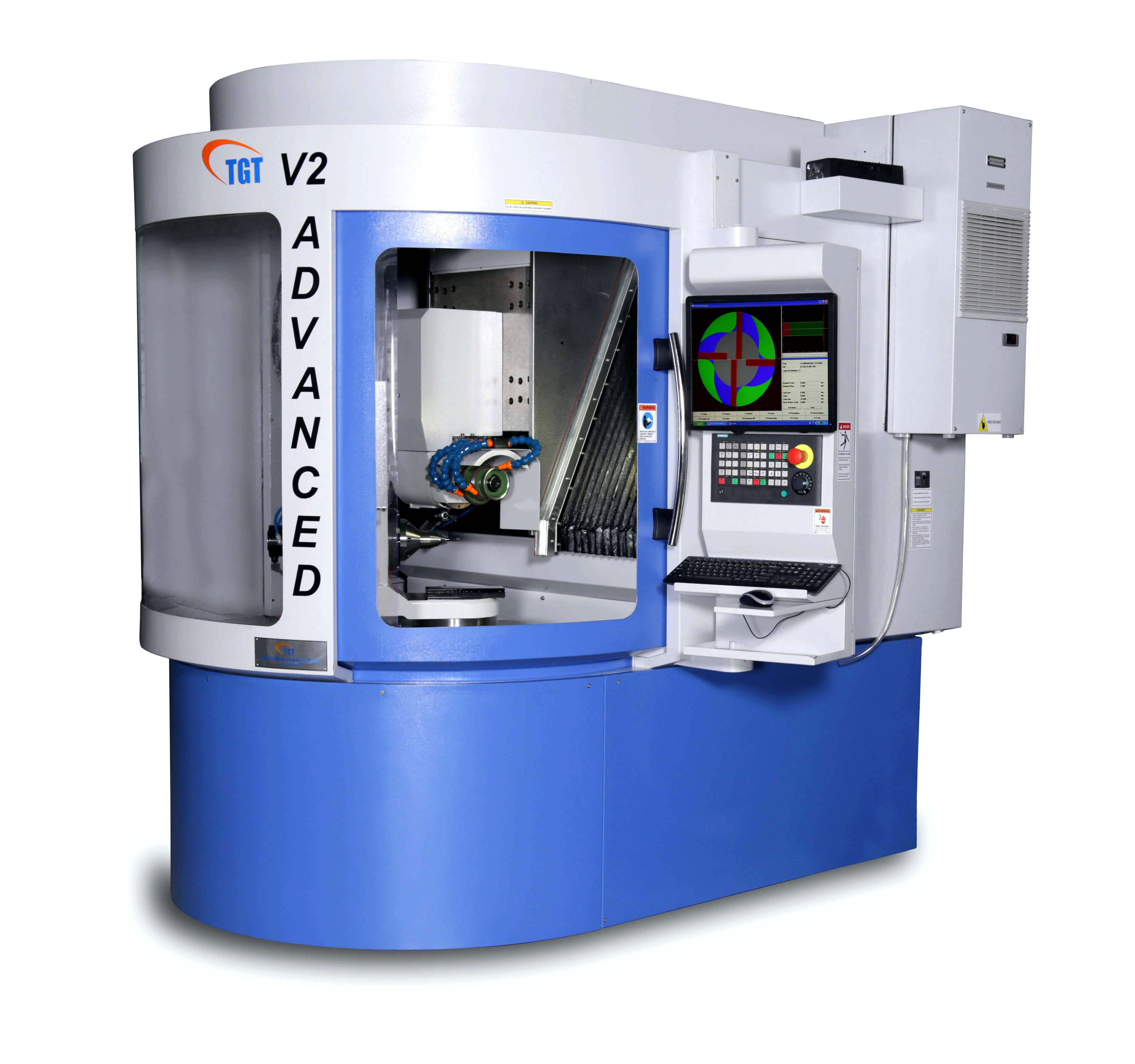

V2 ADVANCED Optima

- V2 ADVANCED Optima is a 5 axes single spindle high precision tool grinding machine. This machine is optimized for grinding diameter range from 2mm to 20mm solid carbide, in multiple settings.

- The machine kinematics and selection of features are well balanced to achieve high precision & excellent surface finish on the tools produced.

- “Split type worm wheel gear” for the tool swiveling axis delivers high level of absolute accuracy with zero backlash.

- Highly balanced spindle ensures cutting edge stability while grinding precision end mills/form tools.

- Electrical elements are designed to reduce the electromagnetic interference & reduced emissions to make the machine environment friendly.

Machine axes configuration

- Roller type LM guide used on this machine will enhance rigidity.

- Optional linear scale & rotary encoder make this machine more accurate.

Advantage of elevated axis design

All the 3 linear axes are isolated from the coolant area. Additionally bellows will protect the ball screws and lm guide ways from coolant splash/carbide sludge. This will enhance the life of the machine & its performance interms of retaining the precision over a long time.

Optimized axis movement for high performance & accuracy

- The ball nose cutter is very closely held to the ‘C’ axis center which makes wheel movement very small interms of X, Y, Z axis.

- This improves the quality of profile/radius generated. This also optimizes the cycle time by the way of short movements.

- V2 ADVANCED Optima is equipped with highly efficient spindle motor of 10 HP continuous power to allow bigger diameter solid carbide tools to be ground with less number of passes.

- Low run out and highly repeatable tool clamping system.

- The taper type spindle system for wheel mounting will ensure very low run out which minimizes the wheel wear and hence enhances it’s life.

- Types of tools manufactured & reground include end mills, ball nose, CR end mill, drill & step drill, form tools, gundrill, inserts, thread mill, taps, form radial cutter etc.

- User friendly MTS –AG software to manufacture/regrind tools. Profile simulation, 3D simulation guides the operator to design the proper tool.

- "Collision check" feature will help to decide the tool length , collet system etc to ensure trouble free running of the machine.

- ISO programming with the help of user parameter is also possible.

| Downloads |

|---|

| Reach Us |

|---|

Plot No.467 - 469, 12th Cross

4th Phase , Peenya Industrial Area

Bangalore - 560058 |

1

1 2

2 3

3 4

4 5

5 MTS SCREEN

MTS SCREEN 3D SIMULATION

3D SIMULATION PROFILE SIMULATION

PROFILE SIMULATION